MAINTENANCE AND OVERHAUL

Revamping, i.e. the overhaul and modernization of mechanical presses, allows machines nearing the end of their functional cycle to be given a “new lease of life” by replacing or repairing worn mechanical, electrical and electronic parts.

Revamping also makes it possible to ensure the safety of all machines that no longer comply with legal requirements and are therefore unable to operate.

During this phase, it is also possible to arrange and carry out modifications to the specific characteristics of the press such as: the stroke, the ram adjustment, the number of strokes per minute, the die light, etc. with our Technical Department.

Thirty years of experience in the construction and overhaul of mechanical presses has enabled Maxipress to become a reference point for the revamping of mechanical presses of any make and model, guaranteeing professional and competent service.

Maxipress is also able to search and find used presses according to the customer’s needs and adapt them so that they can meet the needs of the end user. A “tailor-made” work that allows us to satisfy all possible requests.

Revamping of mechanical presses means a complete overhaul of the machinery, which includes a series of steps and processes necessary to restore the machinery to its original state.

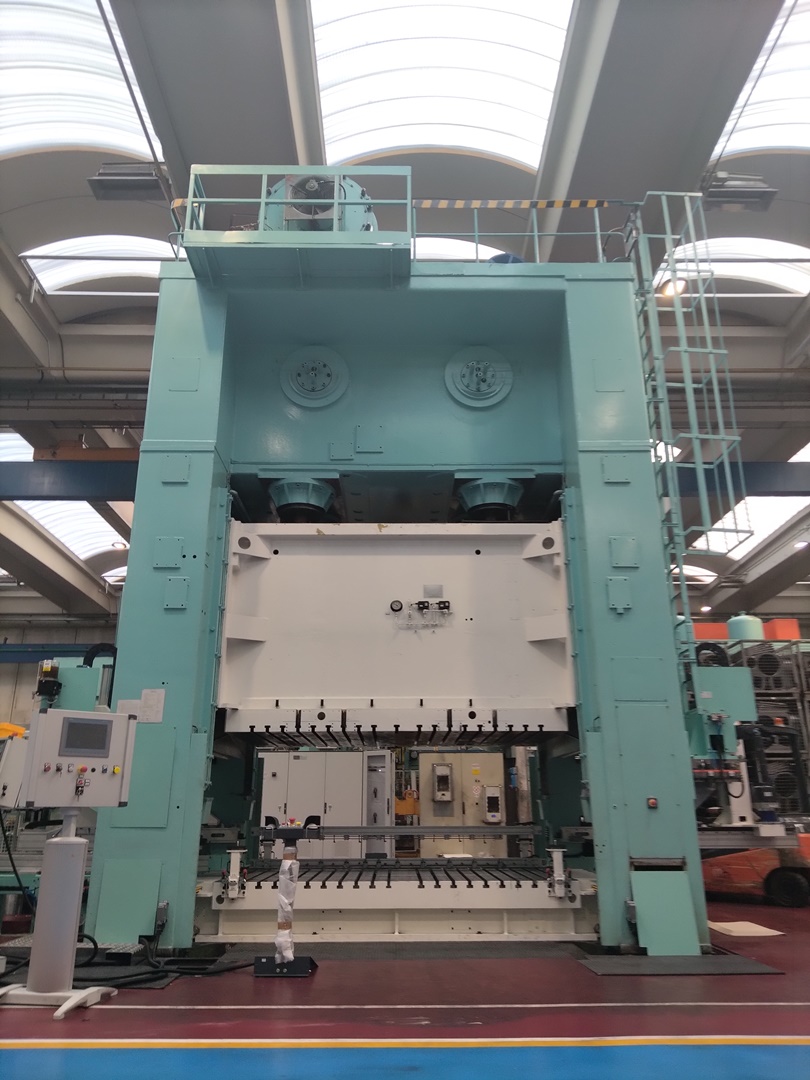

MECHANICAL PRESS BEFORE AND AFTER REVAMPING

DOUBLE UPRIGHT PRESS - SLOWED DOWN - ISGEC

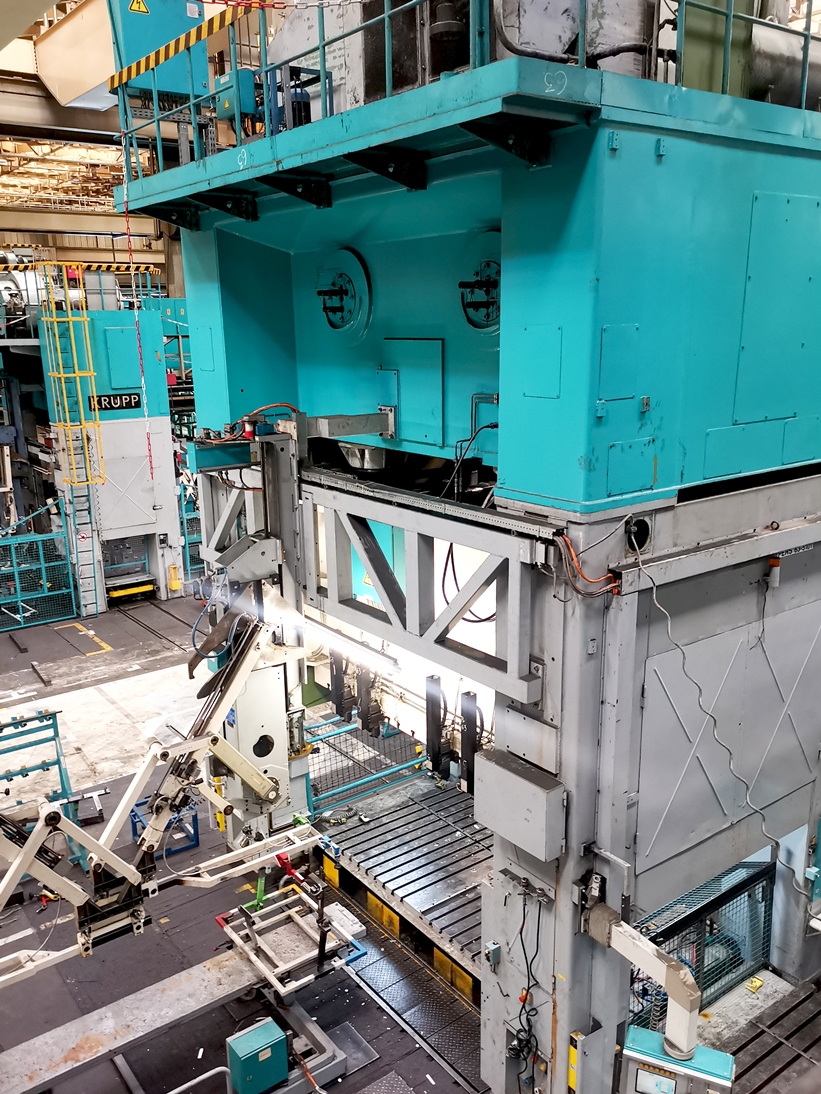

REVAMPING OF THE KRUPP 800 kN PRESS

MECHANICAL PRESS OVERHAUL PROCESS

- Transport of the press to the company headquarters in Arcore

- Dismantling of all components

- Checking of all components and replacement of worn parts

- Professional cleaning of all components

- Painting of various components

- Reconditioning in accordance with current regulations

- Transport to the Customer’s premises

- Reassembly and installation

- Testing and commissioning

WARRANTY

All presses built or serviced by Maxipress are covered by warranty. Maxipress guarantees a fast and continuous after-sales service.

TIMING

Our network of domestic and international suppliers allows us to promptly supply any commercial part.

Thanks to the synergy between our technical department and the production department we are able to acquire and rebuild any mechanical part in a very short time.